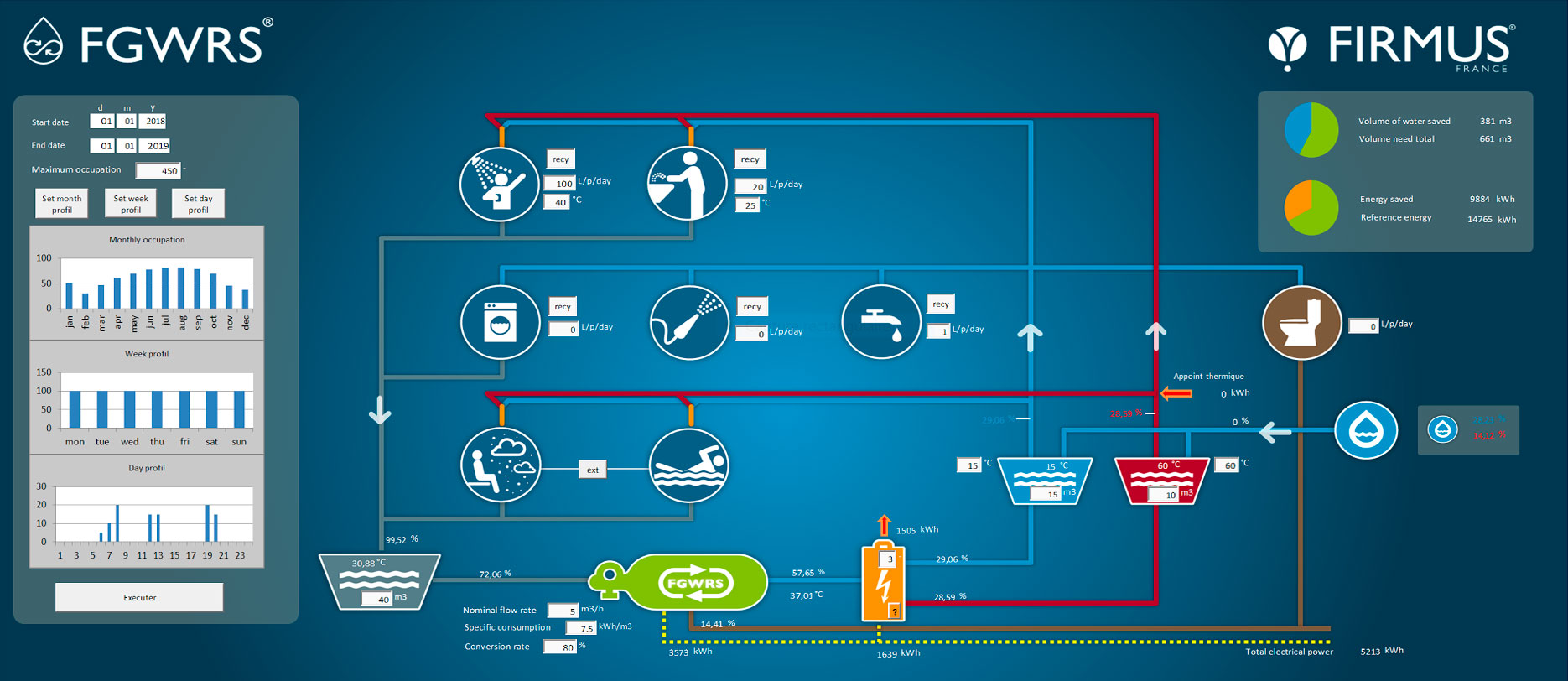

Recycling grey water from sinks, showers, laundry, dirty dishes, floors, and cooking represents an important step for protecting drinking water resources. Recycling 80% or more of this grey water results in substantial savings in terms of both usage costs and resource consumption. This can lead to significant savings when water costs are high. Combined with a calorie collection process, grey water recycling also offers significant energy savings (the temperature of gray water is often higher than 20°C).

This issue is even more important for public installations that consume high quantities of water, such as hotels, public swimming pools, hospitals, clinics, laundry services, etc.

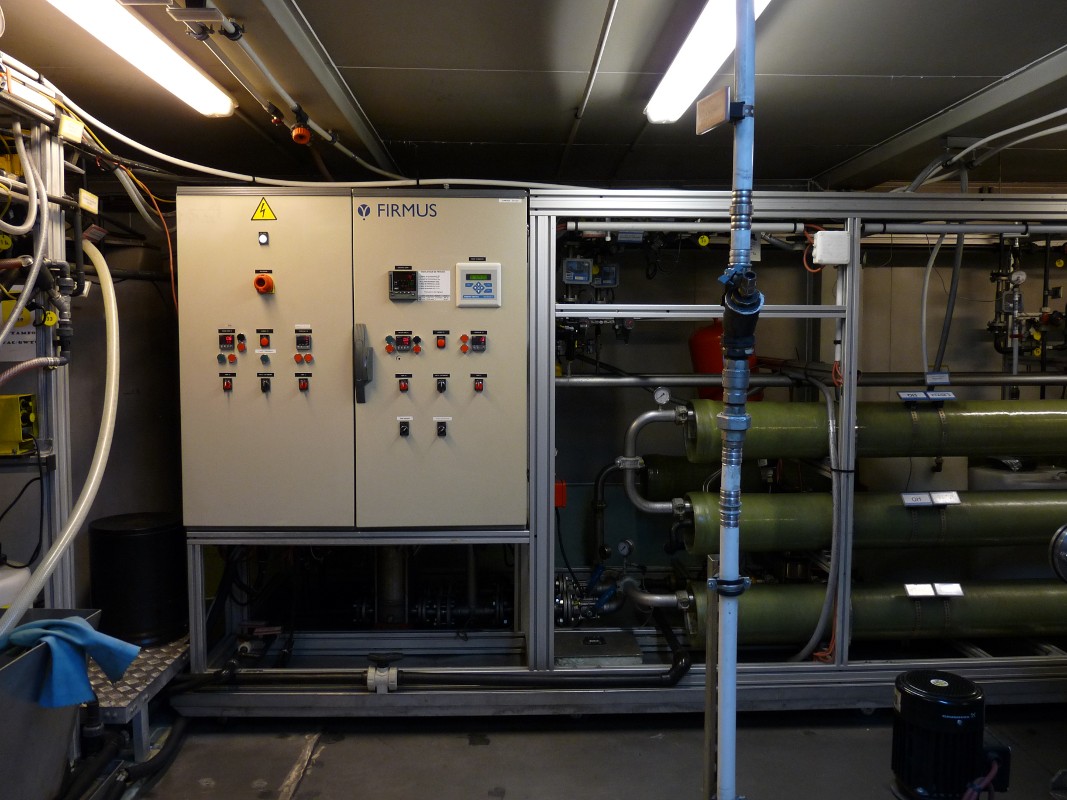

FIRMUS France has developed a specific grey water recycling technology called FGWRS based on that which was setup in 2005, in cooperation with the European Space Agency (ESA) at the Concordia station in Antarctica for the French Polar Institute, Paul Emile Victor (IPEV) and the Italian Antarctica Research Program (PNRA). This treatment unit offers a daily treatment capacity up to 2,400 or 2,800 litters, the equivalent grey water production of approximately 25 people. The unit was designed by FIRMUS France‘s technical director, who is still in charge of monitoring the system today.

This technology, which includes a purification process using organic and inorganic membrane technologies, recycles between 75% and 85% of grey water. Depending on the requirements and sanitary standards to be respected, the process used for this solution can produce drinking quality water, enabling full recycling back into the sanitary network (showers and washbasins).

We develop this technology FGWRS from Monaco through a consortium with Optimal Solutions (leader), SHERPA Engineering (service provider in system engineering) and MRI (to define elements enabling to respect country-specific health standards).

The technology developed by our consortium is widely approved since more than 1,000 people in Concordia Station have used recycled grey water so far, while its hygienic quality has been constantly checked since 2005.